aqdewf

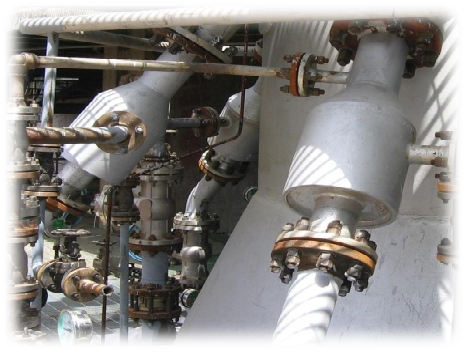

CS Fluid Catalytic Cracking (FCC) Feed Nozzle from China

We Look Forward to a Win-Win

International Cooperation with You Sincerely

Luoyang Sende Petrochemical Engineering Co., Ltd., Henan Province, China

Luoyang Sende Petrochemical Engineering Co., Ltd. (Sende), located in Luoyang, a thousands-year-old capital of China, is a company dedicated to research and development on the petrochemical engineering equipment. More than 100 employees are working in Sende now including researchers, engineers and workers.

Chairman and chief engineer of Luoyang Sende Petrochemical Engineering Co., Ltd; director of the Professional Committee of China Petrochemical Engineering Institute; engaged in petrochemical equipment developing and manufacturing for more than 30 years

Born in 1955 in Shandong Province, China; one of the first batch of the college graduates after China's reform and opening up

Have ever served as multiple occupations including the educated youth, accountant, worker, teacher, vice principal of middle school, manager of state-owned enterprises and founder of Sende

Have played basketball for more than 50 years

Sende owns more than 50 patents covering the fluid catalytic cracking (FCC) unit equipments, the furnace and the crude oil electric desalting equipment, etc.. These techniques are now used in more than 200 commercial units in China, central Asia and Africa.

We have founded 2 research & development institutions, i.e., the Henan Residue Oil Fluid Catalytic Cracking (RFCC) Feed Nozzle Research Center and the Luoyang Atomization Nozzle Research Center.

Sende has cooperated with China scientific research institutes and universities, and collaboratively developed a number of novel techniques such as CS FCC feedstock nozzle.

Sende has organized a team whose members are the experts of different Chinese enterprises to troubleshoot the operating problems for various FCC units in China for many times, put forward optimizations based on the sampled data and the micrograph of the spent catalysts; which were praised by Academician Junwu Chen, the founder of China FCC.

Sende has ever organized and hosted the China FCC Technology Conference for 3 times.

Application Effects of CS FCC Feed Nozzle

Increase the target product yield: intensify the mixing of catalysts with feed in riser reactor; the liquid yield (the total yields of gasoline, LPG and diesel) increases at least 0.3%

Decrease the undesirable by-products: coking in riser decreases considerably, so that the opational life time of the units is prolonged

Low spray velocity at the nozzle outlet: the spray velocity is lower than 65m/s, decreasing the breakage of catalysts notably

High adaptability for feed: it can be operated stably and efficiently even if under the condition of residue oil blending ratio 100%

High operating flexibility: it can be operated in high efficiency under the condition of 60%~130% design flowrate

Low energy consumption: the total pressure drop is less than 0.4 MPa

By 2022, CS feed nozzle has been used in 120 China commercial FCC/RFCC units with different capacity and pattern, including the largest FCC unit in China. The total processing capacity has reached 137.02Mt/a, covering 68.5% of the total capacity of China FCC units.

CS feed nozzle has been used in 12 China commercial DMTO units. It was also used in the world’s largest commercial Pyridine Synthesis unit with 0.025Mt/a, Red Sun Group, Nanjing, China.

CS feed nozzle may supply an incrasing in liquid yield (the total yields of gasoline, LPG and diesel) at least 0.3%.